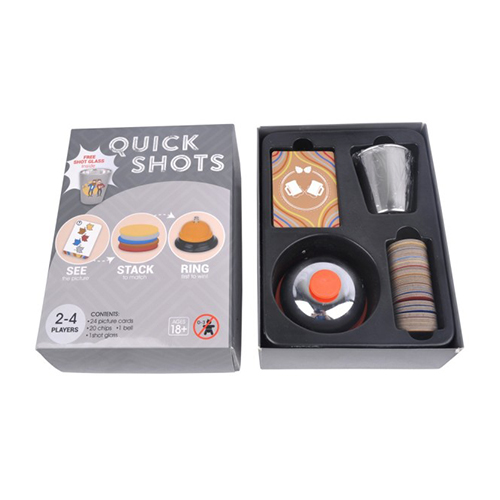

You ordered customized wallets from a manufacturer. When the goods arrived, you’ve checked there were some items that are not good; print was not as specified, some stitches were uncut, zipper colors are different from what you want, product bar codes not in the right place, and so on.

As a buyer you have two options: you can return the items to the supplier for repair or you will assess if these issues are acceptable and you can go ahead and sell the items.

But any of the two would still result to a problem. If you sell it as it is, your customers will think that what you are selling is not of good quality. On the other hand, if you return the items for repair, it will take more time and you would lose money as well.

It is not new in the production business that there will be issues is manufacturing. And that these issues usually come up because of miscommunication with your supplier. Maybe you were not able to specify clearly your standards, instructions were not properly understood by supplier, and so on.

To avoid these types of problems, you need to have an effective communication with your supplier.

What is effective communication?

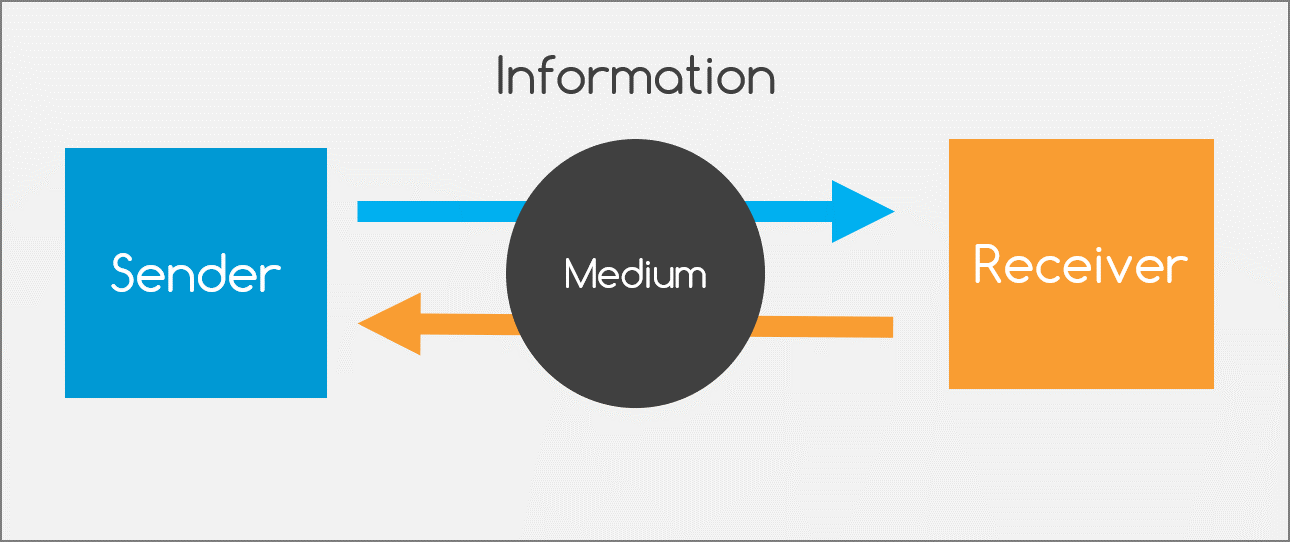

Effective communication as defined, is a process of exchanging ideas, thoughts, knowledge and information such that the purpose or intention is fulfilled in the best possible manner. In simple words, it is nothing but the presentation of views by the sender in a way best understood by the receiver.

Effective communication does not end with the Sender giving information to the Receiver but rather it is only the first step. Effective communication is when the Sender sends the information and upon receiving, the Receiver will be able to understand the message by confirming to the Sender if his understanding of the message is correct.

How do you communicate effectively with your international suppliers?

Let me share with you some tips on how to effectively communicate with your supplier to help avoid manufacturing issues.

1. Keep the Language Simple and Clear

It is important to remember that not everyone has the same fluency with the English language. People in some countries cannot speak and understand the way native English language speakers do. So as an importer, when communicating with suppliers especially in the Far East, you need to talk and write in the simplest and most understandable way. Use words that are common. Make sentences brief, clear and direct to the point. This will help avoid miscommunication and will help to understand each other better.

For example, your supplier sent you third revision of the product design. You want to change just a little more the design and its already good. So you responded “just need to tweak design and it’s good to go.”

What do you mean? What is tweak? Which part of the design should be tweaked? For you it might be understandable but for some it might be different. Since you mentioned “good to go” receiver might assume it’s already okay and proceed with production.

So instead, you can say “Just revise the design a little more. Move the text closer to each other. Send me the revision and we can proceed.”

Comment is clearer and receiver can understand better the instructions.

2. Avoid Conversation on Different Media

In this digital age, sometimes it’s more convenient to communicate with your suppliers through various applications such as What’s App, Skype, We Chat etc. But in order to keep record and to avoid missing information, it is better to communicate through email. With emails, you can easily track the conversations you had with your supplier for reference. It will also avoid missing information if you use one conversation medium versus using a lot of messaging applications.

For example, you mentioned on your email to put gold zippers on the wallet. But along the way you suddenly thought it would be better for the zippers to be in silver color. So you get your phone and sent through Skype this sudden change. The supplier has received it but and responded.

However, during production, the supplier forgot this specification. So he checked on the emails what was stated. Since you’ve mentioned previously on the email that you want gold zippers, the supplier referred to the email and proceeded with production, totally forgetting the sudden change you mentioned on Skype.

I’m not saying you should never communicate with your suppliers through this type of media. You can still mention important details through it but make sure that at the end of the day, you will summarize every important details you mentioned even on phone calls, and send it on email. This will help avoid missing out some information and help avoid problems during manufacturing.

3. Use Visuals

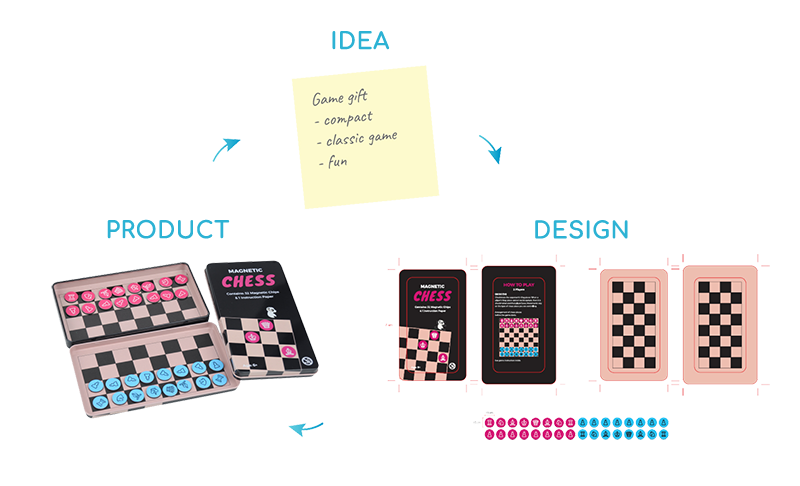

Using other means of communication such as visuals will help make your points more understandable. Make use of visuals to give instructions to your supplier. This can be used for explaining instructions better.

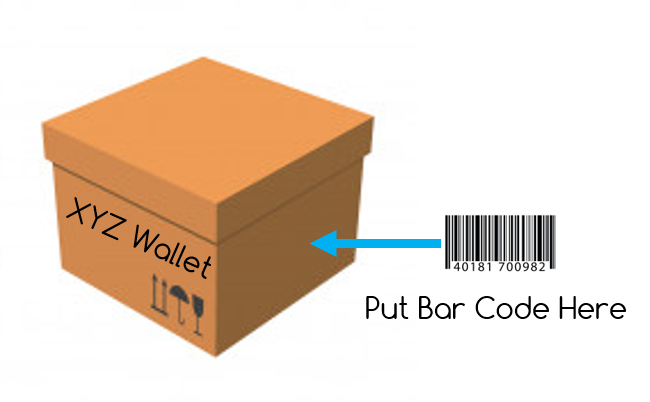

For example you want to tell your suppliers about putting bar codes on the product box.

So you say, put the product bar code on the lower right side of the box.

Where is the lower right side of the box?

Or you can make instructions like this:

Between the two, which is clearer and more understandable?

They say English the universal language but with pictures it will be easier to understand. Visuals offer great help to clear out specific instructions and communicating with people in different cultures especially in the manufacturing industry.

4. Supplier Guide

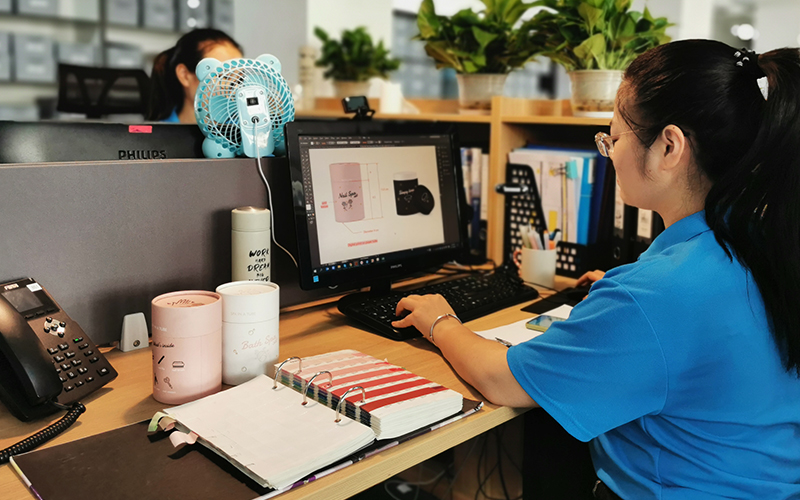

As an importer you sure have your own standards on the condition of your products and how you want them to be. To make sure to inform your suppliers well about these, create a document to summarize everything. You should include your product quality standards (for example, extra stitches of the product should be cut, there should be no burnt edges on the material), manufacturing procedures such as labelling, bar code, packing, and delivery.

You should also attach this guide as well on your purchase order to make sure that this guideline will be followed by the supplier.

This guide or manual will be beneficial to you especially when you are always having transactions with suppliers from different countries. When you already have this type of document, it will help you save time creating new instructions every time you deal with a supplier.

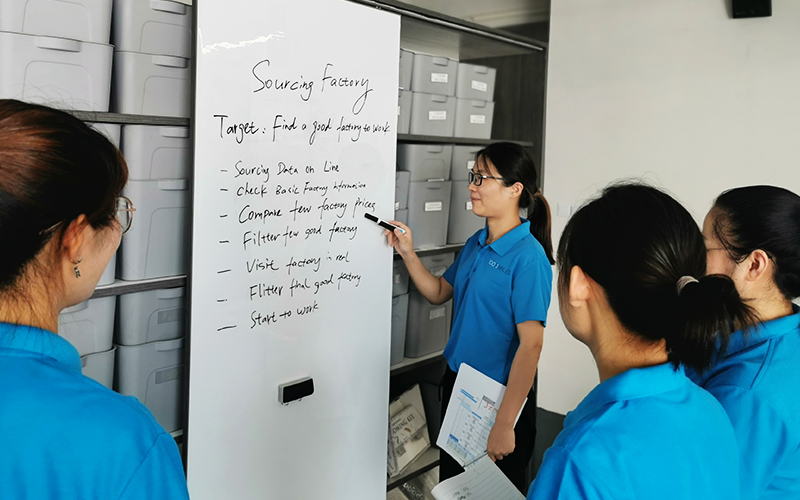

5. Confirmation

As how effective communication should be, you need to make sure that your supplier understands all the things you have mentioned. Making guides and sending emails should not be enough. But rather, you also need to have a constant meeting to ensure that supplier understands well every single instruction, emails, and guides you give. Make time to confirm by working closely with them through having meetings online or personal. It may take a lot of time but if it helps avoiding bigger problems, it will all be worth it.

A lot of problems in manufacturing will arise if communication between you and your supplier is not good. It will cost a lot of resources - time, money, and opportunities if there will be manufacturing errors. But with the help proper and effective communication, all these risks of can be avoided.

Though it may take time to follow all these tips but I am sure it will take you longer to correct manufacturing errors.